| |

| R71 150 KSI All-Thread-Bar - ASTM A722 |

| |

| Nominal Bar Diameter |

Minimum Net Area

Thru Threads |

Minimum Ultimate Strength |

Minimum Yield Strength |

Nominal

Weight |

Approx. Thread

Major Dia. |

Part Number |

1"

(25 mm) |

0.85 in2

(549 mm2) |

128 kips

(567 kN) |

102 kips

(454 kN) |

3.09 lbs./ft.

(4.6 Kg/M) |

1-1/8"

(28.6 mm) |

R71-08 |

1-1/4"

(32 mm) |

1.25 in2

(807 mm2) |

188 kips

(834 kN) |

150 kips

(667 kN) |

4.51 lbs./ft.

(6.71 Kg/M) |

1-7/16"

(36.5 mm) |

R71-10 |

1-3/8"

(36 mm) |

1.58 in2

(1019 mm2) |

237 kips

(1054 kN) |

190 kips

(843 kN) |

5.71 lbs./ft.

(8.50 Kg/M) |

1-9/16"

(39.7 mm) |

R71-11 |

1-3/4"

(45 mm) |

2.60 in2

(1664 mm2) |

400 kips

(1779 kN) |

320 kips

(1423 kN) |

9.06 lbs./ft.

(13.5 Kg/M) |

2" (50.8 mm) |

R71-14 |

2-1/2"

(65 mm) |

5.19 in2

(3350 mm2) |

778 kips

(3457 kN) |

622 kips

(2766 kN) |

18.20 lbs./ft.

(27.1 Kg/M) |

2-3/4

(69.9 mm) |

R71-20 |

** 3"

(75 mm) |

6.46 in2

(4169 mm2) |

969 kips

(4311 kN) |

775 kips

(3448 kN) |

22.3 lbs./ft.

(32.7 Kg/M) |

3-3/64"

(78.2 mm) |

R71-24 |

| |

|

|

|

|

|

|

| |

** The 3" diameter bar is not covered under ASTM A722. |

|

|

| |

|

| |

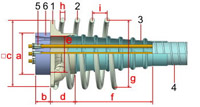

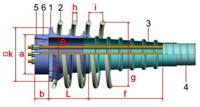

| 1.Bearing Plate |

4.Duct |

| 2.Spiral Reinforcement |

5.Wedge |

| 3.Trumpet Duct |

6.Anchor Head |

|

| |

|

| |

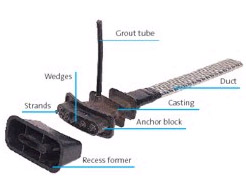

| Life End Anchorage System |

| |

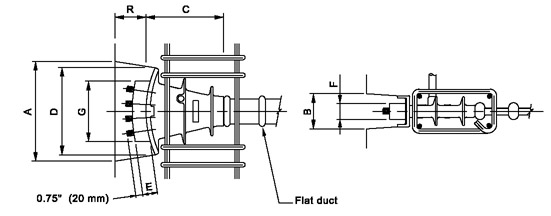

Flat anchorage Post-tensioning System:

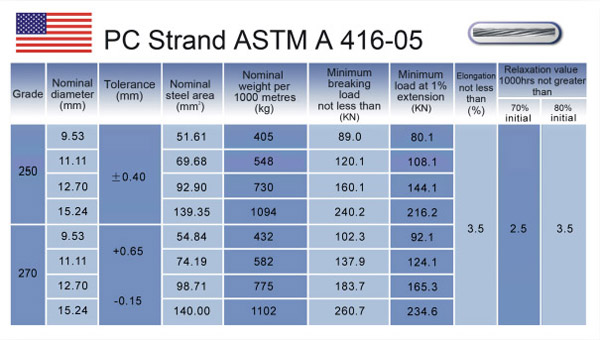

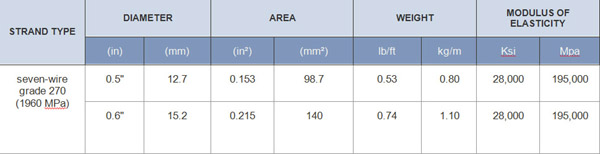

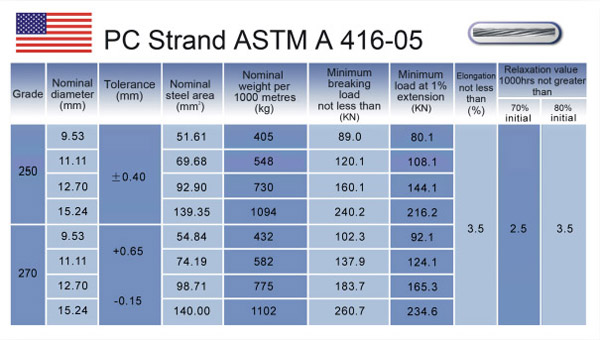

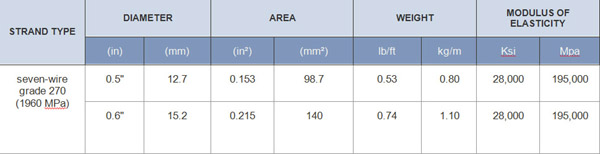

NOOR is a flat-anchorage post-tensioning system using 1 to 5 seven-wire prestressing strands. The prestressing strands have a nominal diameter / nominal cross section of 12.7 mm / 100 mm2, 15.3 mm / 140mm2 or 15.7 mm / 150mm2 and a maximum characteristic tensile strength of 1960 MPa.

The available anchorages are the stressing or active anchorages (Type A), the fixed or passive anchorages (Type F) and fixed as well as movable couplers (Type K). The tendon sheaths are corrugated steel ducts or PT plastic ducts, which are injected with a high performance grout.

The life end anchorage system is normally adopted for bonded tendon. The strands are individually gripped in one slab anchor head unit and transmit their prestressing forces by means of slab type anchor plate casting unit. The strands are stressed individually by means of a mono strand jack. The strands are contained in one flat duct which is made of corrugated galvanized or non-galvanized metal. To ensure corrosion protection and to give adequate bond strength, the tendons are filled with suitable cement grout mix after complete stressing of the strand |

| |

|

| TYPE |

A |

B |

C |

D |

E |

F |

G |

R |

| SA5-4 |

10.42 |

3.7 |

8.5 |

9.75 |

1.75 |

1.96 |

6.75 |

4.33 |

| SA5-5 |

10.42 |

3.7 |

8.5 |

9.75 |

1.75 |

1.96 |

8.75 |

4.33 |

| SA6-4 |

10.42 |

3.7 |

8.5 |

9.75 |

2.24 |

2.64 |

7.51 |

4.33 |

|

| |

| Wedge |

| |

| A wedge assembly typically has 2 or 3 part wedges with a spring wire retainer clip in a groove around the thick end. It is placed around a strand to grip and secure it by wedge action in a tapered hole through a barrel. Available in two nominal sizes, 12.7mm (0.5in) and 15.2mm (0.6in) diameter. |

| |

|

| |

Each individual wedge segment is examined for exact tooth shape bycomputer cameras.

Anchor barrels are manufactured from hightensile crack-tested basic material in a special process, and are only stamped and released for dispatch after final ultrasonic testing.

In this way, we ensure the highest industrial safety and long service life of the anchor components |

| |

| |

| R82 Galvanized Metal Corrugated Duct - ASTM A653 |

| |

|

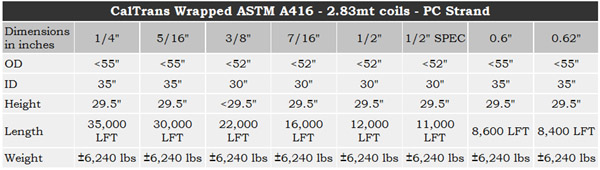

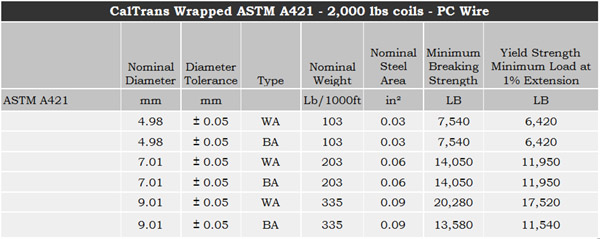

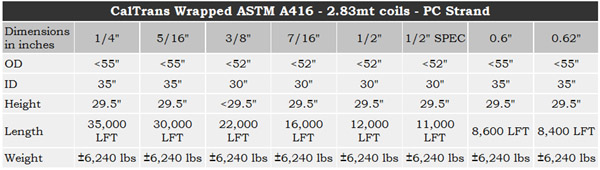

NOOR Galvanized Spiral Metal Duct or High Density Polyethylene Duct meets all physical and structural recommendations for post tensioning duct as laid down by the Post Tensioning Institute (of the United States). The Duct is available in 2”, 3”, and 4” diameter with couplings and reducer couplings for all sizes. |

|

| |

| |

|

|

| |

|

| |

|

| |

|

| |

|